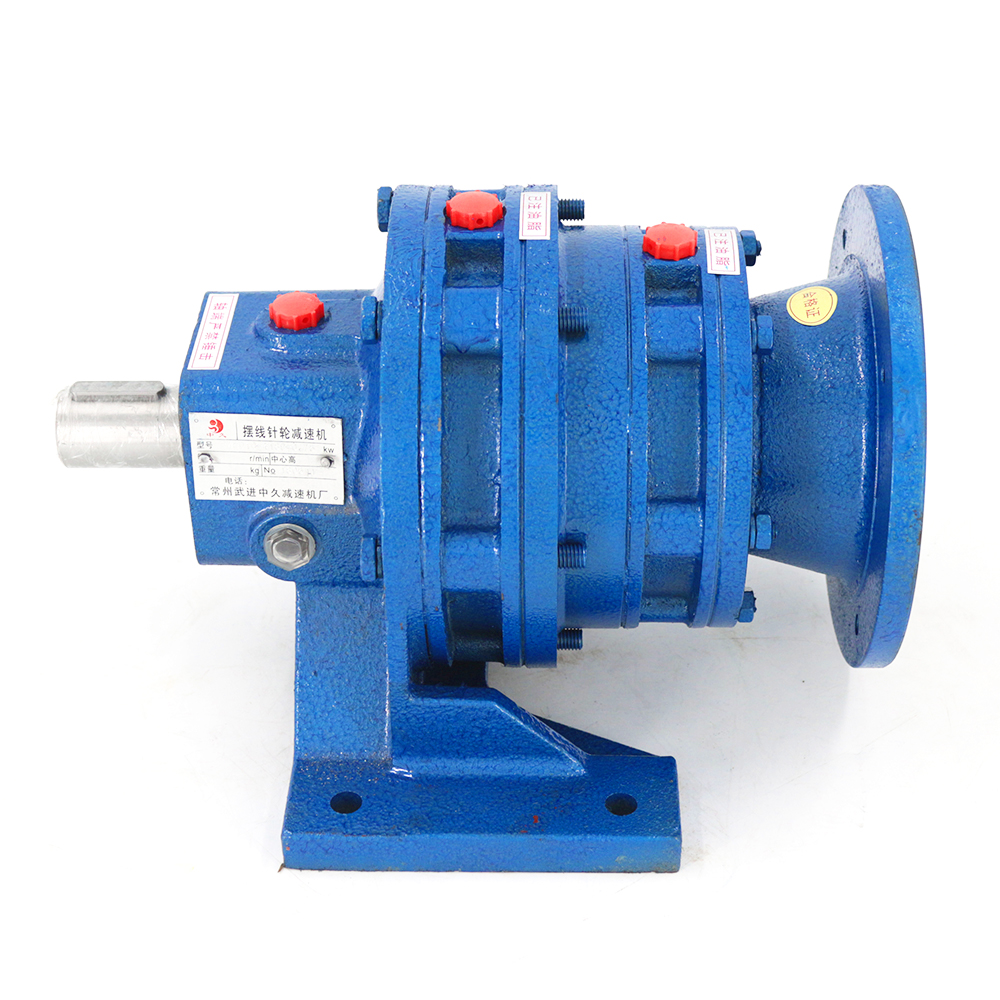

A cycloidal gearbox, also known as a cycloidal push or cycloidal reducer, is a type of gearbox that utilizes a mechanism identified as the cycloidal motion principle to reach velocity reduction and torque multiplication. It is composed of three primary parts: an enter shaft, a established of eccentric pins or cams, and an output shaft.

A cycloidal gearbox, also known as a cycloidal push or cycloidal reducer, is a type of gearbox that utilizes a mechanism identified as the cycloidal motion principle to reach velocity reduction and torque multiplication. It is composed of three primary parts: an enter shaft, a established of eccentric pins or cams, and an output shaft.

Here’s a common overview of how a cycloidal gearbox works:

one. Input Shaft: The input shaft is related to the electricity supply, such as an electrical motor. It transfers rotational movement and torque to the gearbox.

two. Eccentric Pins or Cams: The enter shaft is related to a set of eccentric pins or cams. These pins or cams are off-centre with regard to the enter shaft and are organized in a circular sample all-around it.

three. Cycloidal Disc: Bordering the eccentric pins or cams is a cycloidal disc. The disc has lobes or lobed cutouts that correspond to the range and arrangement of the eccentric pins or cams.

4. Output Shaft: The output shaft is connected to the cycloidal disc. As the eccentric pins or cams rotate with the input shaft, they cause the cycloidal disc to shift in a cycloidal movement.

five. Needle Bearings: The cycloidal disc is supported by needle bearings that allow it to rotate effortlessly and manage get in touch with with the eccentric pins or cams.

6. Output Rotation: The cycloidal motion of the disc converts the rotational motion from the input shaft into an output rotation. The output shaft is related to the cycloidal disc and rotates with it. The output velocity and torque are established by the amount of lobes on the cycloidal disc and the romantic relationship in between the enter and output shafts.

The special feature of a China cycloidal gearbox distributor gearbox is its capacity to accomplish high gear reduction ratios with compact measurement and higher torque output. The cycloidal motion theory permits multiple details of get hold of among the eccentric pins or cams and the cycloidal disc, distributing the load and increasing the gearbox’s torque-carrying potential.

Cycloidal gearboxes are normally made use of in various purposes, including robotics, automation, conveyors, and large equipment, where substantial torque, precision, and compactness are necessary.