5. Extended Product or service Lifecycle: Recycling will allow supplies to be reused and remodeled into new items, extending their lifecycle. This reduces the require for the production of new goods, which usually involves major energy and assets. By maximizing the use of present resources, recycling assists to conserve assets and reduce greenhouse fuel emissions associated with the manufacturing of new products.

five. Sustainable Agriculture: Adopting sustainable agricultural techniques can cut down greenhouse gasoline emissions from the agricultural sector. This involves procedures such as precision farming, natural and organic farming, agroforestry, and effective fertilizer and manure management.

nine. Plan Assist and Financial Incentives:

– Employ supportive insurance policies and rules that really encourage sustainable agricultural techniques and give incentives for emission reductions.

– Supply money guidance and incentives for farmers to adopt local climate-helpful methods and invest in emission-cutting down systems.

9. Authorities Procedures and Global Cooperation: Governments play a crucial part in applying guidelines and regulations that incentivize greenhouse fuel reductions. Applying carbon pricing, environment emission reduction targets, and supporting renewable energy progress are illustrations of efficient plan actions. International cooperation and agreements, this sort of as the Paris Arrangement, help coordinate global initiatives to fight weather improve.

Stay informed about environmental troubles and climate transform.

Engage in conversations and raise recognition among the loved ones and buddies.

Support insurance policies and initiatives that advertise renewable strength and sustainability.

Remember that even though specific actions are significant, collective motion and systemic change are also important to reach major reductions in China greenhouse reducer supplier gasoline emissions. By adopting these steps and encouraging some others to do the similar, people can add to a more sustainable potential.

3. Sustainable Land Use and Forest Conservation:

– Protect and restore forests, as they act as carbon sinks by absorbing carbon dioxide from the atmosphere.

– Implement sustainable land management procedures, such as cutting down deforestation, marketing reforestation, and working towards accountable agriculture.

– Inspire sustainable and minimal-carbon procedures in land-use sectors, which includes sustainable forestry, agroforestry, and sustainable city setting up.

three. Sustainable Transportation: Endorsing sustainable transportation choices can have a sizeable effects on lessening greenhouse gases. Encouraging community transportation, cycling, going for walks, and the use of electric autos can assistance reduce emissions from the transportation sector.

8. Community Recognition and Schooling:

– Raise recognition about the greenhouse impact, local climate transform, and the value of particular person and collective motion.

– Educate communities about sustainable techniques, strength conservation, and responsible intake.

four. Carbon Sequestration: Recycling paper and wood goods encourages the conservation of forests. Forests act as carbon sinks, absorbing carbon dioxide from the ambiance. By lowering the demand for virgin wood goods via recycling, China greenhouse reducer supplier far more forests can be preserved or sustainably managed, allowing for for increased carbon sequestration and decreasing all round greenhouse fuel stages.

Use public transportation, carpool, or bicycle/stroll for shorter journeys.

Choose gas-efficient vehicles or think about electric/hybrid options.

Prepare and merge errands to lessen driving distances.

Consume Extra Sustainably:

It is critical to note that the usefulness of recycling in lowering greenhouse gas emissions is dependent on different factors, these as the effectiveness of recycling processes, the availability of markets for recycled supplies, and customer participation in recycling plans. Nevertheless, recycling remains an critical part of sustainable squander administration strategies and contributes to the general reduction of greenhouse fuel emissions.

2. Strengthen Strength Efficiency:

– Carry out strength-saving steps in residential, professional, and industrial sectors to lower electricity consumption and associated greenhouse gas emissions.

– Enhance infrastructure, appliances, and gear to meet greater energy effectiveness standards.

2. Diminished Landfill Methane: When organic and natural squander, this sort of as foods scraps and property trimmings, ends up in landfills, it decomposes and generates methane gasoline, a strong greenhouse gasoline. By diverting natural and organic squander from landfills as a result of composting or anaerobic digestion, methane emissions can be substantially reduced. These processes capture methane and change it into useful items like compost or biogas, which can be utilized as a renewable power supply.

2. Diminished Landfill Methane: When organic and natural squander, this sort of as foods scraps and property trimmings, ends up in landfills, it decomposes and generates methane gasoline, a strong greenhouse gasoline. By diverting natural and organic squander from landfills as a result of composting or anaerobic digestion, methane emissions can be substantially reduced. These processes capture methane and change it into useful items like compost or biogas, which can be utilized as a renewable power supply.

2. Diminished Landfill Methane: When organic and natural squander, this sort of as foods scraps and property trimmings, ends up in landfills, it decomposes and generates methane gasoline, a strong greenhouse gasoline. By diverting natural and organic squander from landfills as a result of composting or anaerobic digestion, methane emissions can be substantially reduced. These processes capture methane and change it into useful items like compost or biogas, which can be utilized as a renewable power supply.

2. Diminished Landfill Methane: When organic and natural squander, this sort of as foods scraps and property trimmings, ends up in landfills, it decomposes and generates methane gasoline, a strong greenhouse gasoline. By diverting natural and organic squander from landfills as a result of composting or anaerobic digestion, methane emissions can be substantially reduced. These processes capture methane and change it into useful items like compost or biogas, which can be utilized as a renewable power supply. Certainly, helical gears can run in each instructions, which includes managing backward.

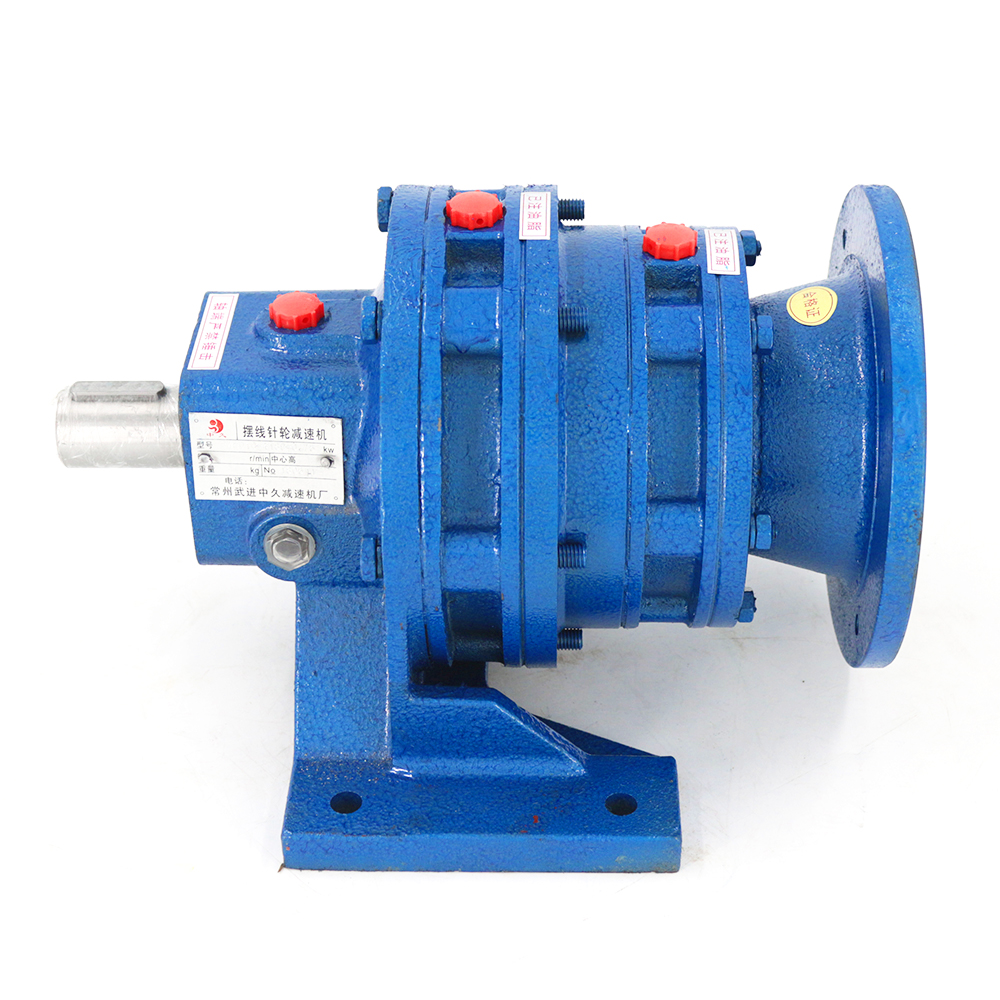

Certainly, helical gears can run in each instructions, which includes managing backward.  A cycloidal gearbox, also known as a cycloidal push or cycloidal reducer, is a type of gearbox that utilizes a mechanism identified as the cycloidal motion principle to reach velocity reduction and torque multiplication. It is composed of three primary parts: an enter shaft, a established of eccentric pins or cams, and an output shaft.

A cycloidal gearbox, also known as a cycloidal push or cycloidal reducer, is a type of gearbox that utilizes a mechanism identified as the cycloidal motion principle to reach velocity reduction and torque multiplication. It is composed of three primary parts: an enter shaft, a established of eccentric pins or cams, and an output shaft.